Researchers Develop Microlens-Augmented AFM for Real-Time Nanoscale Observation and Control

Atomic force microscopy (AFM) is a cornerstone technique for nanoscale manipulation, enabling critical applications in nanoparticle assembly, biomolecule handling, semiconductor device manufacturing, etc. However, conventional AFM systems are fundamentally limited by their inability to provide real-time, high-resolution in-situ imaging during manipulation. This long-standing "manipulation blind spot" has significantly constrained operational precision and efficiency.

Addressing this challenge, a research team led by Prof. YANG Hui at the Shenzhen Institutes of Advanced Technology of the Chinese Academy of Sciences, has developed a novel platform coupling microlens-based super-resolution optics with AFM. This enables real-time super-resolution imaging visual guidance during manipulation, allowing for synchronous imaging and precise control of feature-sized targets down to tens of nanometers.

The study was published in Nano Research on Jun.3.

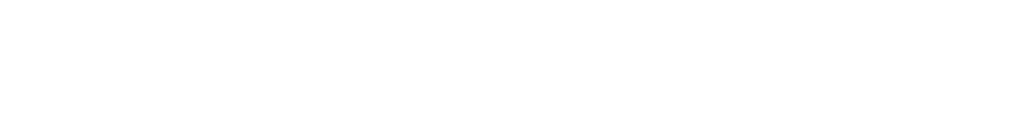

In this study, researchers develop an integrated method that combines super-resolution optical imaging based on microlens technology with AFM manipulation. By coupling a microlens to the end of a conventional AFM probe cantilever and depositing a diamond tip using focused ion beam (FIB), they have designed and fabricated a microlens-AFM probe. The AFM system controls the operating force, speed, and trajectory, while the coupling of the microlens and AFM optical path system provides real-time feedback, improving the efficiency and accuracy of AFM-based nanomanipulation.

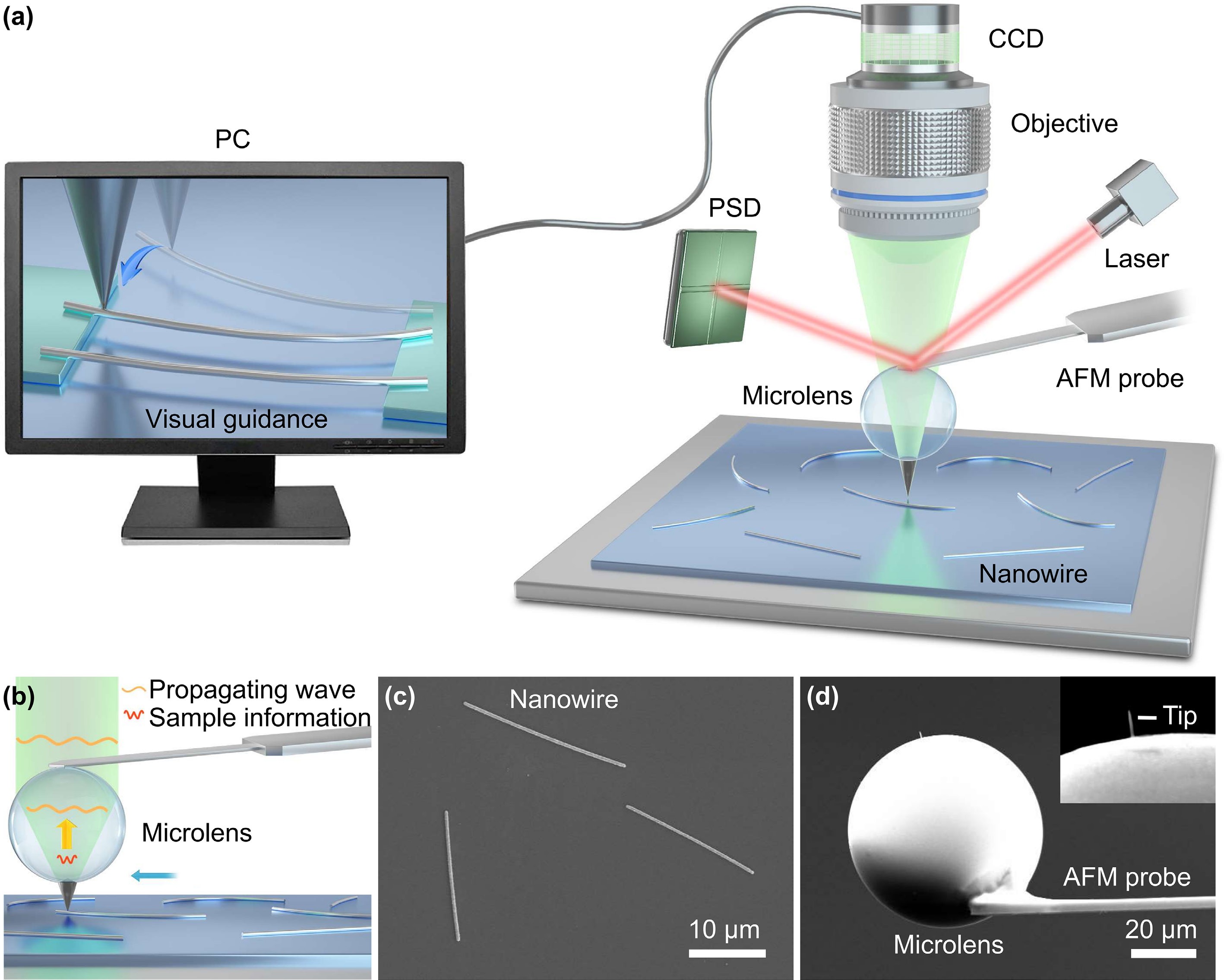

The platform offers a greater than 10-fold improvement in imaging resolution over conventional AFM optical modules, enabling real-time optical tracking and synchronous manipulation of 200-nm silver nanowires under non-destructive conditions. Experimental validation demonstrates over 50% improvement in manipulation accuracy and approximately 200% increase in operational efficiency compared to standard techniques. By providing in-situ, real-time visual feedback during nanomanipulation, the technology effectively successfully overcomes the long-standing "manipulation blind spot".

The probe's modular design ensures compatibility with commercial AFM systems, offering a versatile, cross-disciplinary platform for biosensing, nano-optics, and micro/nano manufacturing research—without the need for equipment modification or overhaul.

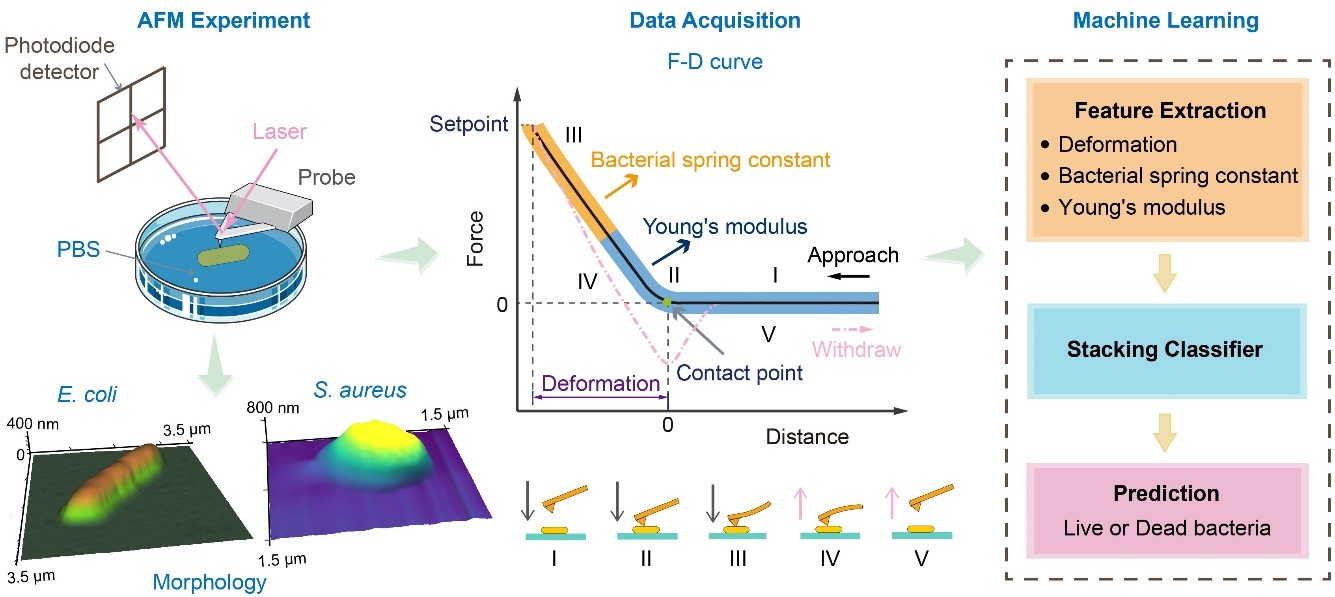

Fig. 1 The paper was selected as a Cover Paper in Nano Research. (Image by SIAT)

Fig. 2 Schematic of the super-resolution observation and synchronous nanomanipulation system. (Image by SIAT)

Fig. 3 Observation and synchronous nanomanipulation of silver nanowires. (Image by SIAT)

File Download: