Novel Microbial Approach for Producing Carbohydrate-Derived Foods and Chemicals from Low-Carbon Molecules

Date:12-12-2023 | 【Print】 【close】

A research team led by Prof. YU Tao from the Shenzhen Institute of Advanced Technology (SIAT) of the Chinese Academy of Sciences (CAS), along with their collaborators, has developed a yeast cell platform capable of converting a variety of low-carbon compounds into multiple carbohydrate derivatives. Through metabolic engineering and glucose inhibition regulation, they achieved high yields of glucose and sucrose, measuring tens of grams per liter.

The study was published in Nature Catalysis on Dec. 5.

While agriculture is crucial for supplying food and raw materials to society, limited arable land and escalating climate change pose significant challenges. Meeting the growing demands is becoming increasingly difficult.

The successful use of low-carbon compounds derived from CO2 reduction for customizing sugar derivatives has been proven. However, not only is the variety of available low-carbon raw materials limited, but also the range of synthesized products is restricted, and sugar yields remain relatively low.

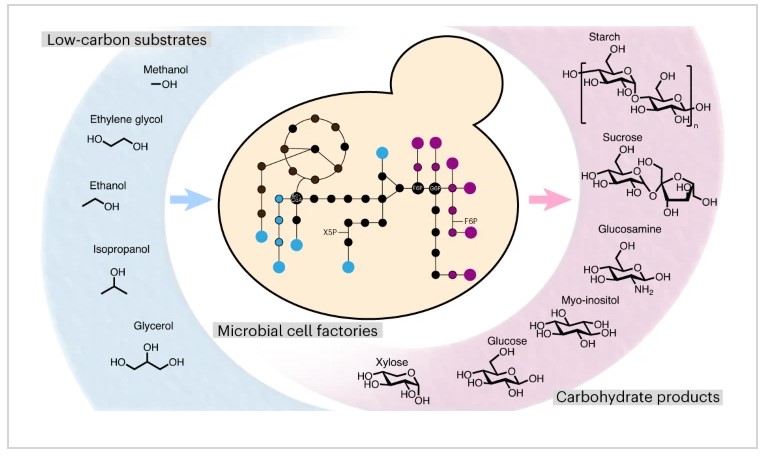

In this study, the researchers proposed a strategy to produce glucose by engineering the microbial transformation of C1–3 products (methanol, ethanol, and isopropanol) from inorganic CO2 fixation.

The researchers first expanded the range of carbon sources for microbial cell factories by studying yeast's utilization of various low-carbon compounds. Apart from ethanol, Saccharomyces cerevisiae can use ethylene glycol (C2), isopropanol (C3), propanoic acid (C3), and glycerol to support cell growth and glucose production. Through engineered Pichia pastoris, methanol (C1) was efficiently converted into glucose, yielding 1.08 g/L in shake flasks and 13.41 g/L in fermenters.

The researchers then utilized ethanol, methanol, isopropanol, and glycerol as carbon sources, diversifying carbohydrates, including xylose, xylitol, myo-inositol, glucosamine, sucrose, and starch. Notably, myo-inositol and glucosamine reached shake flask yields of 228.71 mg/L and 69.99 mg/L, respectively. Sucrose achieved 1.17 g/L in shake flasks and 25.41 g/L in fermenters. Remarkably, microbial production of starch reached 341.59 mg/L in shake flasks, a ubiquitous compound in our lives.

Furthermore, the study introduces an effective method for producing high-carbon compounds using low-carbon sources. In the glucose study, production nearly doubled by regulating glucose inhibition effects.

Additionally, experimental results showed that engineered yeast achieved a protein content of approximately 50% of cell dry weight, indicating this technology promises efficient production of carbohydrate food compounds from low-carbon materials, alongside the byproduct of single-cell protein.

"Our work provides directions for microbial sugar-derived foods and chemicals production from renewable reduced CO2-based feedstocks," said Prof. YU.

Production of carbohydrate products from low-carbon substrates by yeast cell factories. (Image by SIAT)

Media Contact:

ZHANG Xiaomin

Email:xm.zhang@siat.ac.cn