Researchers Propose Highly Flexible and Twistable Flexible Freestanding Magnetic Thin Film

Date:05-06-2020 | 【Print】 【close】

Compared with traditional flexible electronic materials, flexible magnetic materials process many specific advantages like it can be bent, twisted, cut, printed and easily adhered to other items.

In this regard, achieving flexibility for magnetic materials and devices that can be folded and twisted without sacrificing their functional properties are highly desirable.

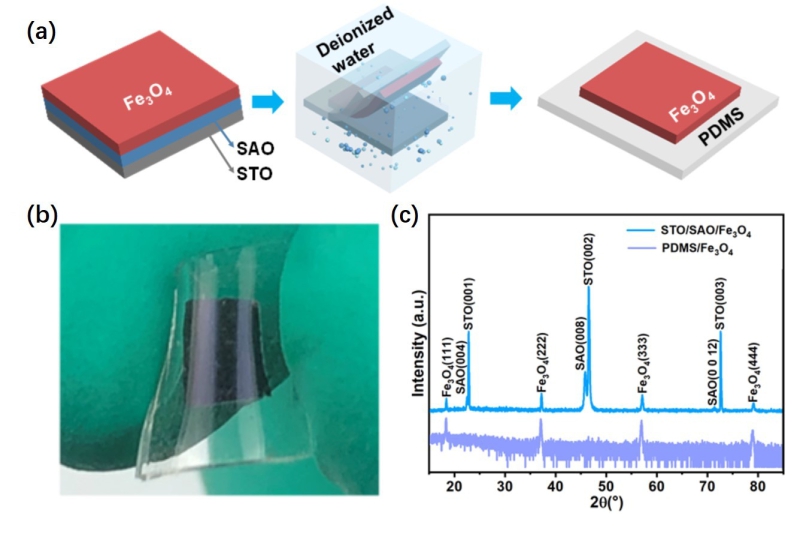

Recently, researchers from the Shenzhen Institutes of Advanced Technology (SIAT), Chinese Academy of Sciences synthesized a high-quality single crystalline freestanding Fe3O4 magnetic thin film by pulsed laser deposition using a water-dissolvable Sr3Al2O6 sacrificial layer, which offered a viable solution for flexible magnetic materials that could be twisted and extended, and freestanding films without substrate constraint.

To conduct this work, the magnetic properties of Fe3O4 thin film were confirmed at multiple length scales by using magnetic hysteresis loops, magnetic force microscopy and Lorentz transmission electron microscopy, respectively. And in-situ scanning electron microscope showed the freestanding Fe3O4 thin film was highly flexible with a bending radius as small as 7.18 μm and twist angle as large as 122°, after which it fully recovered its initial state as well upon unloading, in sharp contrast with bulk magnetite that is quite brittle.

Furthermore, when transferred to a polydimethylsiloxane support layer, the Fe3O4 film could be bent with large deformation without affecting its magnetization, which demonstrated its robust magnetism.

This study, which was published in Advanced Functional Materials, showed a wide range of flexible electronic applications promising in wearable products and implantable systems, including biosensors, soft robots, and artificial neural interfaces.

Figure. (a) Schematic illustration of the synthesis freestanding Fe3O4 thin film; (b) A photograph of bended PDMS/Fe3O4 demonstrating its flexibility; (c) XRD patterns of STO/SAO/Fe3O4 as deposited and flexible PDMS/Fe3O4 after transferring. (Image by SIAT)

ZHANG Xiaomin

Email: xm.zhang@siat.ac.cn