Scientists Propose a Flexible Interface Design for Silicon-graphite Dual-ion Battery

Date:05-03-2020 | 【Print】 【close】

Energy consumption has been amplified sharply in last decades, conventional energy sources are facing great challenges to meet the ever-increasing demand. Since the first commercialization in 1990s, Li-ion batteries (LIBs) are now widely used in fields like electric devices. However, the question remained: the exploited lithium resource in the earth’s crust is very limited and unevenly distributed, and the contained cobalt as redox center in conventional cathode is neither abundant nor environmental friendly, urging the exploration of next generation of low-cost electrochemical energy storage systems (EESSs).

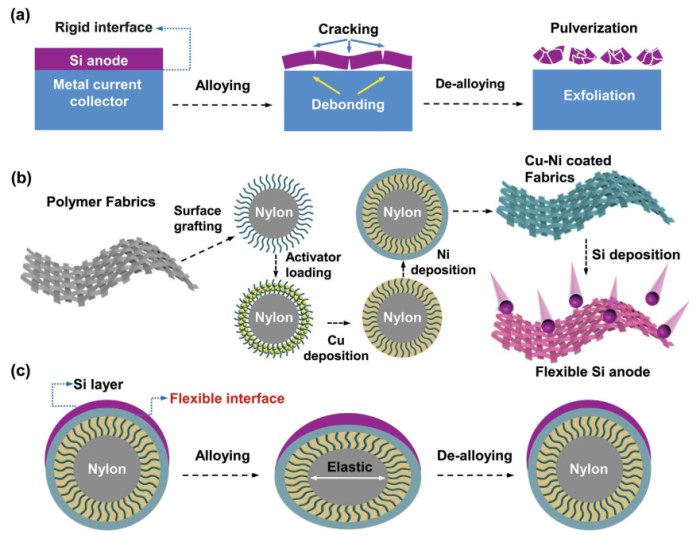

Silicon is abundant in nature with high theoretical capacity (4200 mAh g-1), which is an ideal anode material to improve the energy density of dual-ion batteries (DIBs). However, its application in DIBs has been hindered by the large volume expansion problem (>300%). Although various nanostructures, hollow/porous structures, and composites of silicon have been synthesized to minimize the volume expansion, rigid contacts between silicon and current collectors, which are commonly made with metal foils, resulting in significant interfacial stress. As a consequence, interface cracking and even exfoliation of active materials occur, resulting in unsatisfied cycling performance.

A research group led by Prof. TANG Yongbing and his team members (Dr. JIANG Chunlei, XIANG Lei, MIAO Shijie etc.) from the Shenzhen Institutes of Advanced Technology (SIAT) of the Chinese Academy of Sciences, along with Prof. ZHENG Zijian from The Hong Kong Polytechnic University, have proposed a flexible interface design to regulate the alloying stress of silicon anode, which has been successfully applied to the silicon-graphite DIBs.

The relative research“Flexible Interface Design for Stress Regulation of a Silicon Anode toward Highly Stable Dual-Ion Batteries” has been published online in Adv. Mater. 2020.

The team proposed a flexible interface design to regulate the stress distribution via the construction of a silicon anode on a soft nylon fabric modified with a conductive Cu–Ni transition layer, which endowed the silicon electrode with remarkable fexibility and stability over 50,000 bends. Assembly of the fexible silicon anode with an expanded graphite cathode yielding a silicon–graphite DIB (SGDIB), which possessed record-breaking rate performance (up to 150 C) and cycling stability over 2000 cycles at 10 C with a capacity retention of 97%. Moreover, the SGDIB showed a high capacity retention of ≈84% after 1500 bends and a low self-discharging voltage loss of 0.0015% per bend after 10 000 bends, suggested high potential for high-performance fexible energy-storage applications.

This young research team has been engaged in EESSs study for years, the latest MINIREVIEW named “Mixed polyanionic compounds as positive electrodes in low-cost electrochemical energy storage” has released on Angew. Chem, which gave us a general outline and comprehensive prospect of various energy storage techniques from viewpoints of resources and electrochemical performances. “Low cost is the current trend in the field of energy storage, which urges the exploration of key materials for related devices,” Prof. TANG said, “this work provided an effective approach to enhance the structural stability of alloying anode.”

(a) Schematic illustration of the structural damage of silicon anode with a rigid interface design. (b) Fabrication process of silicon anode with fexible interface design on the soft nylon substrate with a Cu–Ni buffer layer. (c) The detailed structure of the fexible interface, and the shape change of the silicon anode during the alloying and de-alloying process.

CONTACT:

ZHANG Xiaomin

Email: xm.zhang@siat.ac.cn

Tel: 86-755-86585299